Project Status

Week of 02-06-19

Project is: ON TRACK

Although we have run into a few setbacks, primarily in the circuit design, we are still on track to be completed by the deadline.

Issues / Extra progress from last week:

-

Evaluation of the spot welder and assembly of the cells lead to a more traditional approach

-

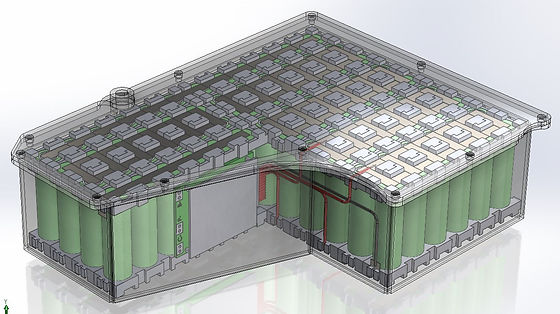

The battery pack was redesigned using interlocking 3D printed holders. These 6x1 battery holders will be configured to fit within an aluminum waterproof enclosure.

-

Sourcing a company to make motor driver PCB

-

Good price and reasonable turn around time

-

Accomplished this week:

Battery pack design:

-

Battery pack was redesigned using a modular 6x1 frame.

-

BMS position was determined andwiring was laid out

-

New welded enclosure was designed with removable cover

Motor Mount adjustments:

-

The 48v BLDC motor was 1mm larger in diameter than specified on the data sheet.

-

Internal Diameter was increased 1mm to compensate for larger outside diameter of the motor

-

Clamp feature was rotated clockwise 75 degrees to allow more room for the battery and better access for tools

Component fit checks:

-

The 48v BLDC motor was a tight squeeze due to the 1mm interference on the OD of the motor

-

The lead on the back side will need a guard and clocked to be out of the way.

-

The throttle potentiometer installed with no issues, the wires are long enough to reach the rear of the bike.

Electrical

-

Continued circuit design

-

Began preliminary circuit testing in MultiSim

-

Began writing code for eBike controller

Goals for next week:

-

Complete circuit design

-

Begin sourcing motor driver PCB

-

Continue code for eBike controller

-

build a test battery pack

-

coordinate with Jeremy Cornwall to use the Randolph campus waterjet

-

Source aluminum plate needed for parts

-

Verify round stock for spacers, turned on lathe at Williston campus

References:

-

ebike school https://www.youtube.com/watch?v=u-4mKh1WaLo&t=463s